Copper Cathode Plate

COPPER CATHODES

Registered Grade A (Cu-CATH-1) | BS EN 1978:1998 | National Standard GB/T 467-2010

Understanding Copper Cathode: A Key Element in Global Trade: –

Grade A copper cathodes are of the highest quality, with a purity of at least 99.99%. They are produced using a state-of-the-art electrolytic refining process that removes impurities.

Copper cathode Grade A is an essential material used in a wide range of applications, including electrical wiring, electronics, construction, and transportation.

Buyer can reduce purchasing costs and ensure the continuity of your business by outsourcing the procurement of copper cathodes to us. Optimized and streamlined logistics processes are the foundation to withstand cost pressure in copper processing. We provide you with the unique opportunity to obtain a long-term, ongoing supply of copper cathodes from Africa and to have your stock refilled several times per month or per quarter.

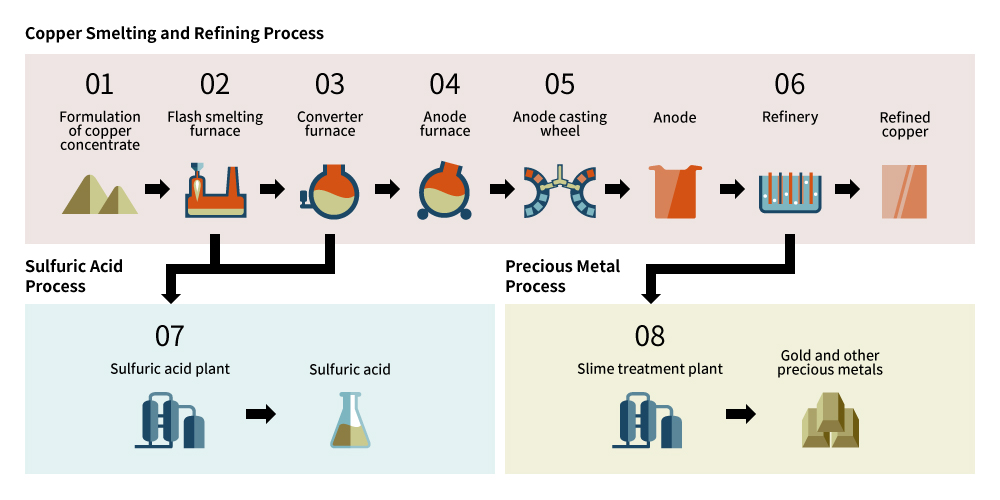

Processing of Sulfide Ore to Copper Cathodes: Sulfide ores are generally processed using pyrometallurgy, the extraction and purification of metals by processes involving the application of heat. This process uses a series of physical steps and high temperatures to extract and purify copper from copper sulfide ores, in four basic steps: 1) froth flotation, 2) thickening, 3) smelting, and 4) electrolysis.

Copper cathodes play a crucial role in the global trade of copper, which serves as the primary raw material for various industries. With its excellent electrical conductivity, ductility and corrosion resistance, copper has become an indispensable metal in fields such as construction, electronics, transportation and power generation. This article aims to provide an in-depth understanding of copper cathode, its manufacturing process and its importance in international trade. Additionally, we will explore influencing factors.

What is Copper Cathode?

Copper cathode refers to a pure form of copper produced through the electrolytic refining process. It is a high-purity copper products with a minimum copper content of 99.95%-99.99%. The cathode undergoes an electrolysis process in which impurities are removed, resulting in a highly refined copper product suitable for various industrial applications. This product is usually produced in large sheets or plates, enabling easy handling and transportation.

Copper cathode specifications:

Copper cathode specifications are crucial in ensuring the quality and suitability of the product for various industrial applications. The specifications typically include the minimum copper content, which is set at 99.95%-99.99% purity level, ensuring a high-grade and refined product. Other specifications may include maximum levels of impurities such as sulfur, oxygen, and other elements, as well as specific physical characteristics such as the size, weight, and shape of the cathode. These specifications are essential for ensuring the consistency and reliability in its use as a raw material for industries such as construction, electronics, and power generation. Adhering to these specifications guarantees that the copper cathode meets the required standards and can perform optimally in various manufacturing processes.

Copper Cathode Price Determinants:

The copper cathode prices are influenced by various factors, including supply and demand dynamics, global economic conditions, production costs, and market speculation. Here are the key determinants affecting prices:

1.Supply and Demand: Fluctuations in global copper demand and supply can significantly impact copper cathode prices. Increased demand from industries such as construction and electrical appliances, particularly in emerging economies, can drive up prices. Conversely, oversupply due to increased production or reduced demand can lead to price declines.

2.Global Economic Conditions: Copper prices are closely linked to the overall health of the global economy. During periods of economic growth, there is typically an increased demand for copper, resulting in higher prices. Conversely, economic downturns can lead to reduced demand and lower prices.

3.Production Costs: The cost of producing copper cathode, including mining, processing, and refining expenses, plays a crucial role in price determination. Factors such as labor costs, energy prices, and transportation expenses can affect the overall production costs and subsequently influence the price.

4.Currency Fluctuations: Copper is a globally traded commodity, and its price is denominated in various currencies. Fluctuations in currency exchange rates can impact the cost of importing and exporting, thereby influencing its price in different markets.

Conclusion:

Copper cathode, with its exceptional properties and versatility, is a key component in global trade. Its production process involves the extraction of copper ore, beneficiation, smelting, and electrolytic refining. The price of copper cathode is influenced by factors such as supply and demand dynamics, global economic conditions, production costs, and currency fluctuations. As an India-based company involved in the transit of copper, your role in facilitating the distribution of copper cathode contributes significantly to various industries’ growth and development worldwide. Understanding the dynamics of copper cathode and its market price is essential for effective decision-making and maximizing the potential of your business in this dynamic industry.

SUPPLY CHAIN ACTIVITIES:

PROCUREMENT:

We now source copper cathodes from Zambia and the Democratic Republic of the Congo, and we are expanding our sources to Chile, Peru and India. These products are offered mainly on long term basis. We promise our international customers a maximum level of continuity in the supply of affordably priced copper cathodes from Africa.

Up to 5,000 MT of copper cathodes can be delivered by us each month. We will eventually be able to increase supplies to 7,000 MT each month by diversifying the seller portfolio.

TRANSPORTATION:

In order to ensure that the items are delivered from the mine or production facility to the loading port in a safe, effective, and timely way, the transport department is essential to the export process. Loading and unloading, transportation, documentation and communication, safety and compliance are some of the actions involved in this operation.

The Road & Rails network efficiently connects our production facilities to loading ports and secure storage facilities. Copper cathode sheet bundles are held together during packaging and transportation using steel strapping.

LOGISTICS:

To ensure that the items are carried from the mine or manufacturing facility to the loading port safely, effectively, and by all applicable regulations and requirements, the logistics department is essential. To guarantee that the entire export process goes smoothly and that the items arrive at their destination on schedule and in good shape, we work closely with the production, customs, and transport departments.The logistics department is essential to the export process because it makes sure that the commodities are efficiently and affordably ransported from the mine or production facility to the loading port. We offer the greatest services in terms of goods forwarding, shipping documents, transportation administration, and cargo insurance.

We provide international containerized and bulk transportation services on FOB, and CIF terms.

PRE-SHIPMENT INSPECTION (PSI):

Pre-shipment activities at the loading port are critical to ensuring that all laws and regulations export the goods, reach their destination on time, and are in good condition.

We collaborate with international pre-shipment organizations such as CCIC, Alex Stewart, Intertek, SGS, Mitrask, etc.

Pre-shipment tasks that frequently occur at the loading port include packing and labelling, inspection and quality control, customs clearance, loading and stowing, and creating and submitting the necessary documentation for the shipment, such as bills of lading, packing lists, and commercial invoices.

Product Details: –

(Electrolytic Copper Grade-A)

HSN CODE – [74031100]

Colour: Brown RED.

Features: High Conductivity Pure Electrolyte

Shape: Square

Dimension: 914mm x 914mm x 12mm (LME Standard).

Weight of Each Sheet: 125 Kg (+/- 1%).

Net Weight of Each Pallet: 2 MT (+/- 1%) Min.

Packing: Palletized Banded by Aluminium Bands.

Weight in Each Container: 20 MT Appx.

Gross Weight Per Container: 22.20 MT Appx.

Origin: DR Congo, Ghana, Zambia and DRC Africa.